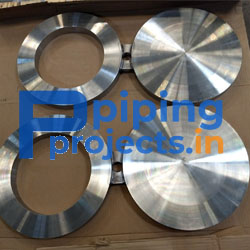

Piping Projects India is one of the leading Spade Flanges Manufacturer & Supplier. Spade Flanges, or spacer flanges, are specialised flanges designed to block pipelines or vessel blockage temporarily. They consist of a spade (a solid piece of metal in the shape of the flange) and a spectacle (a similar piece with an opening). When installed between two flanges, they effectively isolate the section, allowing maintenance or repair work to be conducted safely. Our organization is one of the largest Spade Flanges Supplier in India.

Spade Flanges

Trusted

Supplier

Genuine

Product

Easy

purchase

What is Spade Flanges?

Spade flanges are specialised flanges used in piping systems to isolate components. They consist of two parts: a spade and a spacer. A spade is a flat piece of metal that slides between two flanges in a pipeline. When put between the flanges, it seals off the line and prevents fluid from flowing. Operators can stop the flow of fluid via the pipeline by inserting a spade between the flanges, allowing for safe operation on downstream equipment without totally depressurizing or draining the entire system.

Spade flanges are available in a variety of materials, diameters, and pressure ratings to meet specific application needs. They are typically utilised in pipelines that transport corrosive or hazardous fluids and require equipment isolation for maintenance or repair. This is especially important in industries like oil and gas, petrochemicals, and power generation, where process continuity is critical and downtime is minimised.

Piping Projects India is a leading Spade Flanges Manufacturer in India. This enables a varied range of alternatives, ensuring that customers have access to high-quality Spade Flanges that may be customized to meet their specific application needs. Spade Flanges are available in a variety of diameters and bespoke configurations, some of which are seen here.

Spade Flanges Chemical Composition

A prominent Spade Flanges Manufacturer in India, specializes in ensuring exceptional quality through precise chemical composition. Our Spade Flanges is dependable, robust, and performs optimally, meeting and exceeding industry standards in India and elsewhere.

| ASTM A182 GRADE | C | Mn | P | S | Si | Ni | Cr | Mo | Nb | Ti | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| F304(1) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-11.0 | 18.0-20.0 | – | – | – | – |

| F304H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-11.0 | 18.0-20.0 | – | – | – | – |

| F304L(1) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-13.0 | 18.0-20.0 | – | – | – | – |

| F304N(2) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-10.5 | 18.0-20.0 | – | – | – | – |

| F304LN(2) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-10.5 | 18.0-20.0 | – | – | – | – |

| F309H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 12.0-15.0 | 22.0-24.0 | – | – | – | – |

| F310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.0 | 19.0-22.0 | 24.0-26.0 | – | – | – | – |

| F310H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 19.0-22.0 | 24.0-26.0 | – | – | – | – |

| F310MoLN | 0.030 | 2.0 | 0.030 | 0.015 | 0.40 | 21.0-23.0 | 24.0-26.0 | 2.0-3.0 | – | – | N 0.10-0.16 |

| F316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | – | – | – |

| F316H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | – | – | – |

| F316L(1) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-15.0 | 16.0-18.0 | 2.0-3.0 | – | – | – |

| F316N(2) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | – | – | – |

| F316LN(2) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | – | – | – |

| F316Ti | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | – | (3) | N 0.10 max |

| F317 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | – | – | – |

| F317L | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | – | – | – |

| F321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-12.0 | 17.0-19.0 | – | – | (4) | – |

| F321H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-12.0 | 17.0-19.0 | – | – | (5) | – |

| F347 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | – | (6) | – | – |

| F347H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | – | (7) | – | – |

| F348 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | – | (6) | – | Co 0.20 Ta 0.10 |

| F348H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | – | (7) | – | Co 0.20 Ta 0.10 |

WHERE CAN Spade Flanges BE USED?

Spade flanges are used in a wide range of industrial applications when temporary isolation of piping systems is required for maintenance, repair, or shutdown processes. Spade flanges are widely used in industries that handle hazardous or corrosive fluids, including oil & gas, petrochemicals, chemical processing, and power generation plants.

Spade Flanges Mechanical Properties

As a top Spade Flanges Supplier in India, Our Spade Flanges offers superior mechanical properties, ensuring long-term endurance in critical applications. In India's industrial climate, our precision-engineered equipment performs well and lasts long.

| ASTM A182 Grade | Minimum Tensile Strength in MPa |

Minimum Yield point in Mpa |

Minimum Elongation in % |

Minimum Reduction of in min, % |

|---|---|---|---|---|

| ASTM A182 F304 | 515 | 205 | 30 | 50 |

| ASTM A182 F304L | 485 | 170 | 30 | 50 |

| ASTM A182 F316 | 515 | 205 | 30 | 50 |

| ASTM A182 F316L | 485 | 170 | 30 | 50 |

| ASTM A182 F321 | 515 | 205 | 30 | 50 |

WHERE SHOULD Spade Flanges BE INSTALLED?

Spade flanges should be deliberately put at crucial points in piping systems to provide temporary isolation for maintenance, repair, or shutdown processes. Spade flanges are most commonly installed at pipeline junctions, particularly near valves, pumps, or other equipment that requires isolation. This comprises installations in industries like oil and gas, chemical processing, power production, and water treatment facilities.

Spade Flanges WIDELY USE IN?

Spade Flanges Weight Chart

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Things To Consider When Buying Spade Flanges

Application & uses of Spade Flanges

Supplying Spade Flanges to Following Cities:

Piping Projects India is a leading Spade Flanges Manufacturer in India. We proudly supply high-quality Spade Flanges to major cities in India. We are known in the market as the India’s leading Spade Flanges Supplier for a long time.

| Cities We Supply | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Raigad | Pune | Nashik | Nagpur | Mumbai | |||||

| Ahmednagar | Rajkot | Kolkata | Vadodara | Jalandhar | |||||

Get in Touch