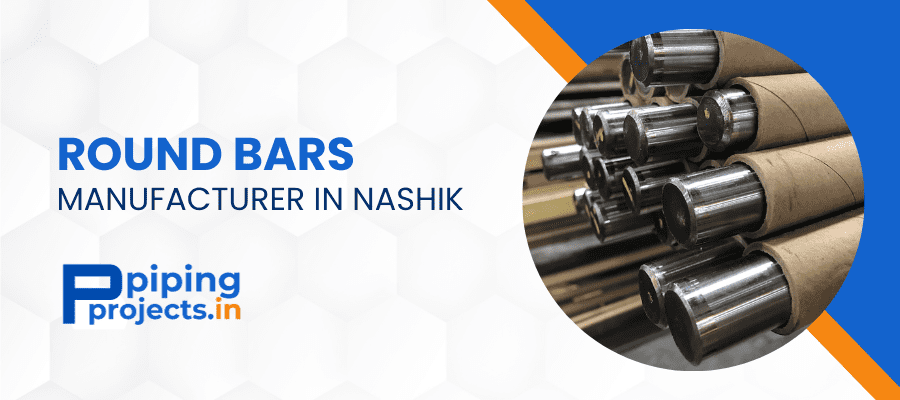

Piping Project is a top-notch Round Bar Manufacturer in Nashik. Our Round Bar is known for its exceptional corrosion resistance properties and its ability to perform effectively in various environments. It exhibits remarkable performance in high-temperature and pressure systems, providing stability and support to various equipment. The Round Bar stock is commonly used in pump shafts, valves, dairy equipment, surgical parts, machine tools, and other similar applications. Piping Projects India is a leading Round Bar Supplier in Nashik.

Round Bar

Stainless Steel

Stainless Steel

SS 301 Bar

SS 301 Bar

SS 310 Bar

SS 310 Bar

Trusted

Supplier

Genuine

Product

Easy

purchase

WHAT IS ROUND BAR?

A Round Bar is an elongated cylindrical metal stock that finds application in various industries. Its exceptional corrosion resistance makes it suitable for deployment in diverse environments. SS Round Bars exhibit superior performance in high-temperature and pressure systems, ensuring reliable operation. These bars are indispensable for providing stability and support to various equipment. Furthermore, rounds are characterized by remarkable versatility and an excellent surface finish. Their good malleability enables them to adapt well to different conditions. These attributes make Round Bars widely used in industries such as pump shafts, valves, dairy equipment, surgical parts, machine tools, and others.

Ss Round Bar Weight Chart

| Hollow Bar | From 32mm O.D x 16mm I.D to 250mm O.D x 200mm I.D |

|---|---|

| Channel Bar | From 5.0 to 6.0mm thickness, 40 x 80 mm to 75 x 150mm section |

| Angle bar size | 20mm*3mm*20mm~100mm*12mm*100mm |

| Threaded Bar Billet Size | From 1/2 to 495mm Dia. |

| Rectangular Bars Section | From 3.0 to 12.0mm thickness |

| Rectangles Size | 30 x 33 mm to 1066 x 295 mm |

| Tolerance | H8 to K12 |

| Dimensions | ASME, EN, DIN, BS, JIS, ASTM, AISI |

| Condition | Hardened, Tempered and Annealed |

| Standard | AMS 5513, AMS 5647, ASTM A276, ASTM A479, AMS 5511 |

| Round Bar Size | Bar Diameter between 3-~800mm |

| Technique | Hot Rolled, Cold Rolled, Cold Drawn, Rod, Forged Round Bar |

| Surface | Hairline, Sand Blasting Finished, Bright, Cold Drawn, Hot Rolled Pickled, Polished |

| Processing | Bar cutting up to 650mm |

WHAT ARE THE BENEFITS OF PURCHASING ROUND BAR FROM Piping Projects India?

Piping Projects India is a top-notch Round Bar Supplier in Nashik, renowned for delivering Round Bar made up of superior quality raw materials that cater to the diverse requirements of our esteemed clientele. Benefit of purchasing Round Bar from Piping Projects India highlighted below :

Piping Projects India is a leading Round Bar Manufacturer in Nashik . Our products are in various diameters, catering to diverse utility and intended purposes.

WHY TENSILE TESTS REQUIRED FOR STAINLESS STEEL BARS AND RODS ?

Tensile tests are a necessary requirement for stainless steel bars and rods as they yield vital insights into the mechanical properties and strength of the material. Stainless steel finds extensive application across diverse industries such as construction, automotive, aerospace, and manufacturing, where its mechanical performance assumes paramount importance. The process of tensile testing entails subjecting a sample of the stainless steel to a controlled force until it reaches its ultimate breaking point. This examination aids in the determination of crucial properties such as tensile strength, yield strength, and elongation, all of which play a pivotal role in evaluating the material's appropriateness for its intended application.

Stainless Steel Round Bar Weight Chart

| Weight | Dia. | Dia. | Wght |

|---|---|---|---|

| (ton) | (cm) | (inches) | per metre (ton) |

| 0.0006 | 0.3 | 1/8 Inch | 0.00006 |

| 0.0001 | 0.4 | 3/16 Inch | 0.00014 |

| 0.00016 | 0.5 | 1/4 Inch | 0.00025 |

| 0.00022 | 0.6 | 5/16 Inch | 0.00039 |

| 0.0003 | 0.7 | 3/8 Inch | 0.00056 |

| 0.0004 | 0.8 | 7/16 Inch | 0.00077 |

| 0.00062 | 1 | 1/2 Inch | 0.001 |

| 0.00089 | 1.2 | 9/16 Inch | 0.00122 |

| 0.00122 | 1.4 | 5/8 Inch | 0.00156 |

| 0.0014 | 1.5 | 11/16 Inch | 0.00189 |

| 0.00159 | 1.6 | 3/4 Inch | 0.00225 |

| 0.0021 | 1.8 | 7/8 Inch | 0.00307 |

| 0.00248 | 2 | 1 Inch | 0.00403 |

| 0.003 | 2.2 | ||

| 0.00357 | 2.4 | ||

| 0.00388 | 2.5 |

STEEL ROD VS BAR

Steel Rods are typically cylindrical, although they can also possess a square cross-section. These Rods are appropriately dimensioned and are often subjected to tempering before machining. They are commonly used to produce steel shafts, drill bits, taps, dowel pins, and similar items. On the other hand, the steel bar is a lengthy product typically manufactured in round, square, rectangular, or hexagonal cross-sections. These bars exhibit high strength and possess a pleasing surface finish. They find widespread usage in both industrial and commercial applications.

Piping Projects Design and Equipment Arrangements

How can I protect round bars from corrosion?

Stainless Steel Round Bar Dimensions in Mm, Inches

| Diameter (inches) | Diameter (mm) | Tolerance (inches) | Tolerance (mm) | Length (feet/meters) |

|---|---|---|---|---|

| 1/4" | 6.35 | ± 0.002" | ± 0.051 mm | Up to 20' (6 meters) |

| 3/8" | 9.525 | ± 0.003" | ± 0.076 mm | Up to 20' (6 meters) |

| 1/2" | 12.7 | ± 0.004" | ± 0.102 mm | Up to 20' (6 meters) |

| 5/8" | 15.875 | ± 0.005" | ± 0.127 mm | Up to 20' (6 meters) |

| 3/4" | 19.05 | ± 0.006" | ± 0.152 mm | Up to 20' (6 meters) |

| 1" | 25.4 | ± 0.008" | ± 0.203 mm | Up to 20' (6 meters) |

| 1-1/4" | 31.75 | ± 0.010" | ± 0.254 mm | Up to 20' (6 meters) |

| 1-1/2" | 38.1 | ± 0.012" | ± 0.305 mm | Up to 20' (6 meters) |

| 2" | 50.8 | ± 0.016" | ± 0.406 mm | Up to 20' (6 meters) |

| 2-1/2" | 63.5 | ± 0.020" | ± 0.508 mm | Up to 20' (6 meters) |

| 3" | 76.2 | ± 0.024" | ± 0.610 mm | Up to 20' (6 meters) |

Things To Consider When Buying Round Bar From Manufacturer in Nashik

Stainless Steel Cold Rolled Bar Stock Sizes

| Type | ISO Tolerance | Sizes (mm) | Sizes (Inches) |

|---|---|---|---|

| Peeled and Ground | h9-h10-h11 | 20.00 – 50.00 | 3/4 – 2.00 |

| Cold Drawn and Ground | h8-h9-h10-h11 | 10.00 – 75.00 | 5/6 – 2.50 |

| Cold Drawn and Polish | h8-h9-h10-h11 | 3.00 – 75.00 | 1/8 – 3.00 |

| Peeled and Polished | h11, h11-DIN 1013 | 40.00 – 150.00 | 1.50 – 6.00 |

Application & uses of Round Bar Manufacturer in Nashik

Supplying Round Bar to Following Cities:

Piping Projects India is a leading Round Bar Manufacturer in Nashik. We proudly supply high-quality Round Bar to major cities in India. We are known in the market as the India’s leading Round Bar Supplier for a long time.

| Cities We Supply | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Raigad | Pune | Nashik | Nagpur | Ahmednagar | Mumbai | ||||

| Ahmedabad | Bangalore | Chennai | Vadodara | Ludhiana | Delhi | ||||

Get in Touch