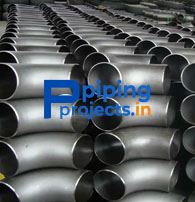

Piping Projects India is one of the leading Pipe Fitting Manufacturers. Pipe Fittings are crucial components in plumbing systems, facilitating the connection and redirection of pipes to ensure efficient fluid flow. From residential homes to industrial complexes, Pipe Fittings play a vital role in maintaining the integrity and functionality of plumbing networks.

Pipe Fittings serve multiple purposes within plumbing systems. They enable changes in pipe direction, branch connections, and alterations in pipe diameter, ensuring the seamless flow of liquids or gases. Without proper fittings, plumbing systems would lack versatility and adaptability to various installation requirements.

Pipe Fittings serve as essential components in plumbing and industrial systems, facilitating the seamless flow of fluids or gases. They are instrumental in connecting pipes, redirecting flow, and accommodating changes in direction or diameter.

By enabling the creation of complex piping networks and providing options for maintenance and repairs, Pipe Fittings play a pivotal role in ensuring the efficiency and reliability of various systems. Whether it's residential plumbing, commercial HVAC installations, or industrial applications, the proper selection and installation of Pipe Fittings are crucial for optimal performance and safety.

As a trusted Pipe Fitting Manufacturer in India, our products are utilized in a wide range of applications, including plumbing, pipe networks, and pressure applications. These fittings join pipes and allow for the efficient flow and control of fluids and gases. Depending on the application and needs, SS Pipe Fittings can be joined with mechanical welding or threading at the ends.

Pipe Fittings

Trusted

Supplier

Genuine

Product

Easy

purchase

Piping Projects India is the market's leading Pipe Fitting Suppliers. Our products are available in a number of sizes to meet a wide range of needs and intended applications.

Ready to Purchase this Product Today?

Contact us now for quick help.

Pipe Fittings Grades & Materials We Supply

Piping Projects India is a reputable Pipe Fittings company that is committed to provide high-quality, dependable Pipe Fittings solutions, which made us a well-known Pipe Fitting Manufacturer in India.

| Material | Grade |

| Stainless Steel | 200 Series - 201, 202, 205.

300 Series 301, 302, 303, 304, 304L, 308, 309, 309S, 310, 310S, 314, 316, 316L, 316TI, 317, 317L, 321, 347. 400 Series 405, 409, 429, 430, 430F, 430FSe, 434, 436, 442, 446, 403, 410, 414,416, 416Se, 420,420F, 422, 431, 440A, 440B, 440C. 500 Series - 501, 502. 600 Series - 630 (17-4 PH). |

| Titanium | Titanium 6-4, Gr 1, Gr 2, Gr 3, Gr 4, Gr 5, Gr 7, Gr 9, 5-2.5, 6-2-4-2, 6-4 ELI, 6-6-2. |

| Hastelloy | C22, C276, X, B-2. |

| Monel | 400, K500. |

| Nickel Alloy | Nickel 200 Nickel 201, Alloy 20, Alloy 286, Alloy 218 (Nitronic 60), Nitronic 50 (XM-19). |

| Cupro Nickel | Cu 90-10 (C70600,CW352H), Cu 70-30 (C71500, CW354H). |

| Inconel | 601, 625, 660A, 718, X-750, 825, 925, 608. |

| Duplex / Super Duplex | D S31803, D S32205, SD S32750, SD S32760, SD S32950. |

| Chromium Molybdenum Steel | A387 Gr 2, A387 Gr 12, A387 Gr 11, A387 Gr 22, A387 Gr 22L, A387 Gr 7, A387 Gr 21, A387 Gr 21L, A387 Gr 9, A387 Gr 91. |

| Nichrome Alloy | CrNi 20/80. |

| Copper | ASTM B1, ASTM B2, ASTM B3, ASTM B152, ASTM B124, ASTM B133. |

| Brass | Alloy 260, Alloy 272, Alloy 330, Alloy 353, Alloy 360, Alloy C48200 - C48500, Alloy 464. |

| Bronze | Alloy 954, Alloy 933. |

| Case Hardening Steels | 10C4, 15C8, 15Cr3, 16Mn5Cr4, 20MnCr5, 15Ni5Cr4Mo1, 15Ni5Cr4Mo2, 20Ni7Mo2, 20NiCrMo2, 14CrNi6. |

| En Series | En8, En9, En19, En24, En30B, En31, En36, En45, En47, En48. |

| Mild Steel | Sae 4118, Sae 4120, Sae 4120, Sae 4130, Sae 4135, Sae 4137, Sae 4140, Sae 4142, Sae 4145, Sae 4147, Sae 4150, Sae 4161, Sae 8620. |

Advantages of Buttweld Fittings

Buttweld Fittings present a range of significant advantages. Their exceptional corrosion resistance makes them ideal for harsh environments, ranging from chemical processing to marine settings. They maintain strength and integrity even at high temperatures, ensuring reliability in demanding conditions. The seamless design of Buttweld Fittings reduces the risk of leaks and enhances structural integrity, critical in pipelines and pressure vessels.

Stainless steel's aesthetic appeal, durability, and ease of maintenance are additional benefits, making it a cost-effective choice for various industries. Its compatibility with different alloys and ease of welding further contribute to its versatility and make it a preferred option in constructing and maintaining pipelines and systems.

Other Best Selling Types

Ready to Purchase this Product Today?

Contact us now for quick help.

What is the difference between reducing & equal tee

Equal tees are typically used when there is a need to split the flow of a fluid or substance into three equal parts or when connecting pipes of the same size. An equal tee, alternatively referred to as a straight tee, possesses three outlets that are of identical size. In essence, the diameter of the branch or side outlet corresponds to that of the run or main pipe.

Reducing tees are employed when connecting pipes of varying sizes, facilitating a smooth transition from a larger pipe to a smaller one while ensuring an uninterrupted flow. These tees prove especially advantageous in applications with disparities in flow rate or pressure requirements between the primary and secondary pipes.

Pipe Fitting Size Chart

Discover our extensive Pipe Fitting Size Chart, which contains comprehensive size information and alternatives from reputed Pipe Fitting Suppliers in India.

| Nominal Pipe Size | Outside Diameter |

90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| (mm) | (inches) | Center to Face | Center to Face | Center to Face | Radius | Center to Center | Back to face | |

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

What are the popular grades of Pipe Fittings?

We stand out as a leading Pipe Fitting Supplier in India. Our extensive inventory allows us to have a variety of Pipe Fittings with different grades in stock, such as:

Pipe Fitting Dimension Chart

Explore our complete Pipe Fitting Dimension Chart, which includes accurate dimensions and specs from a major Pipe Fitting Manufacturer in India.

| NPS in Centimeter |

O.D. In MM | 90 Degree Elbow | 45 Degree Elbow |

Buttweld Tee | Buttweld Cap | |

|---|---|---|---|---|---|---|

| Long Radius A |

Short Radius A |

B | C | E | ||

| 1.27 | 21.336 | 1-1/2 | – | 5/8 | 1 | 1 |

| 1.905 | 26.67 | 1-1/8 | – | 7/16 | 1-1/8 | 1-1/4 |

| 1 | 33.401 | 1-1/2 | 1 | 7/8 | 1-1/2 | 1-1/2 |

| 2.54 | 42.164 | 1-7/8 | 1-1/4 | 1 | 1-7/8 | 1-1/2 |

| 2.54 | 48.26 | 2-1/4 | 1-1/2 | 1-1/8 | 2-1/4 | 1-1/2 |

| 5.08 | 60.325 | 3 | 2 | 1-3/8 | 2-1/2 | 1-1/2* |

| 5.08 | 73.025 | 3-3/4 | 2-1/2 | 1-3/4 | 3 | 1-1/2 |

| 7.62 | 88.9 | 4-1/2 | 3 | 2 | 3-3/8 | 2* |

| 7.62 | 101.6 | 5-1/4 | 3-1/2 | 2-1/4 | 3-3/4 | 2-1/2* |

| 10.16 | 114.3 | 6 | 4 | 2-1/2 | 4-1/8 | 2-1/2* |

| 12.7 | 141.3002 | 7-1/2 | 5 | 3-1/8 | 4-7/8 | 3* |

| 15.24 | 168.275 | 9 | 6 | 3-3/4 | 5-5/8 | 3-1/2* |

| 20.32 | 219.075 | 12 | 8 | 5 | 7 | 4* |

| 25.4 | 273.05 | 15 | 10 | 6-1/4 | 8-1/2 | 5* |

| 30.48 | 323.85 | 18 | 12 | 7-1/2 | 10 | 6* |

| 35.56 | 355.6 | 21 | 14 | 8-3/4 | 11 | 6-1/2* |

| 40.64 | 406.4 | 24 | 16 | 10 | 12 | 7* |

| 45.72 | 457.2 | 27 | 18 | 11-1/4 | 13-1/2 | 8* |

| 50.8 | 508 | 30 | 20 | 12-1/2 | 15 | 9* |

| 55.88 | 558.8 | 33 | – | 13-1/2 | 16-1/2 | 10 |

| 60.96 | 609.6 | 36 | 24 | 15 | 17 | 10-1/2 |

| 66.04 | 660.4 | 39 | – | 16 | 19-1/2 | 10-1/2 |

| 76.2 | 762 | 45 | 30 | 18-1/2 | 22 | 10-1/2 |

| 86.36 | 863.6 | 51 | – | 21 | 25 | 10-1/2 |

| 91.44 | 914.4 | 54 | 36 | 22-1/4 | 26-1/2 | 10-1/2 |

| 106.68 | 1066.8 | 63 | 42 | 26 | – | 12 |

What is PVC Pipe Fitting?

A PVC Pipe Fitting is a component used to connect two pipes or tubing. These fittings are applicable in both mechanical and plumbing operations. They are called connectors and can be manufactured from various materials. PVC, which stands for polyvinyl chloride, is an inexpensive and user-friendly material. PVC pipes, typically grey, are commonly used for water supply and drainage purposes, accommodating both clean and dirty water. Additionally, PVC pipes conceal electrical cables and prevent them from being exposed or hanging on walls or the ground.

Things To Consider before Buying Pipe Fitting From Manufacturer In India

As a top tier Pipe Fitting Manufacturer in India, we proudly supply high-quality Pipe Fittings to major cities in India. We are known in the market as a trusted Pipe Fitting Supplier in India for a long time.

| Top Pipe Fitting Supplier in Indian Cities | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Raigad | Pune | Nashik | Nagpur | Ahmednagar | Mumbai | ||||

| Ahmedabad | Bangalore | Chennai | Vadodara | Ludhiana | Delhi | ||||

Pipe Fitting Manufacturer in India

Pipe Fitting Supplier in India

Get in Touch