Piping Project is one of the leading Instrumentation Valve Manufacturer in Nashik. A wide range of Instrumentation ball valves, constructed from diverse materials and available in various sizes, can be found in the market. The instrumentation ball valve, among these valves, is commonly employed in process measurement and control systems across multiple industries. This valve is characterized by a spherical component with a central port that enables the regulation and cessation of fluid flow. Piping Projects India is a top Instrumentation Valve Supplier in Nashik.

Instrumentation Valve

Stainless Steel

Stainless Steel

SS 301 Grade

SS 301 Grade

SS 310 Grade

SS 310 Grade

Trusted

Supplier

Genuine

Product

Easy

purchase

WHAT ARE INSTRUMENTATION VALVES?

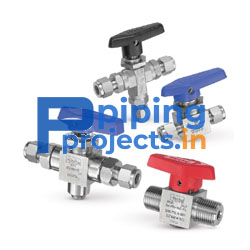

A fluid measurement system employs a variety of valves, including the Instrumentation valves, which serve as the primary safeguard for safety and quality within the system. These valves are utilized for a range of functions, including measuring, isolating, blocking, and bleeding static pressure, venting, pressure gauge differential pressure, and more. We are a leading Instrumentation Valve Manufacturer and other different countries. The Instrumentation control valves are operated under the guidance of a controller in order to effectively manage and regulate the flow of fluid. This enables precise control over various aspects of the process quality, including but not limited to level, temperature, and pressure, as well as direct control of flow rate.

HOW TO CHOOSE THE RIGHT INSTRUMENTATION MANIFOLD VALVES?

We are a top notch Instrumentation Valve Supplier, The most asked questions from client is How to choose the right instrumentation manifold valves. The selection of appropriate instrumentation manifold valves is of utmost importance in guaranteeing industrial processes’ safety, dependability, and efficiency. In order to arrive at a well-informed decision, it is imperative to carefully contemplate a multitude of pivotal factors.

Firstly, it is necessary to evaluate the application’s specific requirements, including pressure, temperature, and the type of fluid or gas being controlled. Secondly, the valve type, such as needle, ball, or double block and bleed valves, should be determined based on the desired flow control and shut-off capabilities. The construction material should also be considered, ensuring compatibility with the process media and environment.

Piping Projects India is a leading Instrumentation Valve Manufacturer in Nashik. Instrumentation Valve available in various diameter and types some of the types mention below.

Stainless Steel Instrumentation Valve Chemical Composition

A premier Instrumentation Valve Manufacturer in Nashik, specializing in stainless steel valves, carefully ensures superior quality through a precise chemical composition. Our valves are reliable, durable, and function optimally, meeting and exceeding industry requirements in Nashik and beyond.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

HOW DOES AN INSTRUMENTATION CHECK VALVES WORK?

The valves within the piping system are activated by the pressure of the fluid passing through them, and will close in the event of any reverse flow. In situations where the flow direction is reversed, the valves on the instrumentation manifold are deemed to be self-actuating, thus protecting the piping system against potential harm caused by the water hammer. Instrumentation check valves are used to avert the incidence of such events.

Ss Instrumentation Valve Mechanical Properties

As a leading Instrumentation Valve Manufacturer in Nashik, our stainless steel valves have exceptional mechanical qualities that ensure durability and lifespan in crucial applications. Our precision-engineered instruments deliver outstanding performance and durability in Nashik's industrial landscape.

| Grade | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

|---|---|---|---|---|

| S32750 | 7.8 | 0.281 | 1350 | 2460 |

DIFFERENT TYPES OF INSTRUMENTATION VALVES

Piping Projects India is a popular Instrumentation Valves Supplier in Nashik, We supply Different grades of Instrumentation valves, Some of the grades mention below.

WHERE SHOULD INSTRUMENTATION RELIEF VALVES BE INSTALLED?

Installing these valves near the tank and adjacent to a cold water line is advisable. Despite their limited usage, they serve a vital purpose in the instrumentation that requires their implementation. Instrumentation relief valves are considered to be cost-effective and time-efficient. Furthermore, they provide a safety measure by allowing for swift water drainage in an emergency.

INSTRUMENTATION VALVE WIDELY USE IN?

Specification of Instrumentation Valve

| Size Range | Flow Patterns | End Connections |

|---|---|---|

|

|

|

| Below listed High Pressure Ball Valve Suppliers also stock following brands | Types | Threads |

|

|

|

| Testing | Parts | List of projects where below listed High Pressure Ball Valve manufacturers has supplied |

|

|

|

| High pressure stainless steel ball valves types | Media temperature range | Standards |

|

-45 °C (-50 °F) to 121 °C (250 °F) |

|

| Pressure Rating | Media | Seal Types |

|

|

|

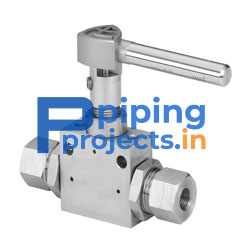

WHAT ARE SOME ADVANTAGES OF INSTRUMENTATION ROOT VALVE?

The aforementioned valves possess the capacity to withstand a pressure of 6000 Psi and are primarily utilized in applications that operate in both liquid and gaseous states. They are deemed reliable for throttling functions. The instrument root valves are predominantly employed for the purpose of isolating pressure within the system. Stainless steel instrumentation valves are regarded as a safety mechanism and a time-saving device as they prevent the pressure from surpassing the maximum allowable limit in the piping system. In the absence of instrumentation isolation valves, the pressure may exceed the permissible limit, leading to a catastrophic system failure.

It is imperative that instrumentation limited control valves are not capped, as this allows for excess water to drain. Additionally, the drain pipe must be positioned below the valves. The selection of the appropriate instrumentation tools control valve is crucial in maintaining the pressure below the system’s permissible limit.

Things To Consider When Buying Instrumentation Valve From Manufacturer in Nashik

Application & uses of Instrumentation Valve Manufacturer in Nashik

Supplying Instrumentation Valve to Following Cities:

Piping Projects India is a leading Instrumentation Valve Manufacturer in Nashik. We proudly supply high-quality Valves to major cities in Nashik. We are known as the India’s leading Valves Supplier for a long time in the market.

| Cities We Supply | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Raigad | Pune | Nashik | Nagpur | Mumbai | |||||

| Ahmednagar | Rajkot | Kolkata | Vadodara | Jalandhar | |||||

Get in Touch