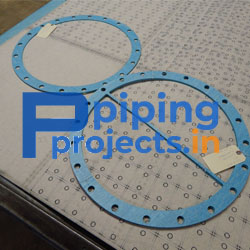

Piping Projects India is one of the leading Low Pressure Gasket Manufacturer in India. A low-pressure gasket is a sealing component used to prevent fluid or gas leaks in systems that operate at low pressures. Our organization is one of the largest Low Pressure Gasket Supplier in India. These gaskets are commonly employed in situations where the pressure applied to the sealing connection is minimal, such as plumbing systems, car engines, and tiny machines.

Low Pressure Gasket

Trusted

Supplier

Genuine

Product

Easy

purchase

Piping Projects India is an esteemed Low Pressure Gasket, is dedicated to providing with reliable, top-notch Gasket. Here are the specifications for Low Pressure Gasket

| Gasket | Specifications |

|---|---|

| Product Name | Low Pressure Gasket |

| Thicknesses | 1mm, 1.5mm, 2mm, 3mm |

| Class | 150# TO 2500# |

| Temperature range | -20°C to 120°C |

| Type of Gasket | Metallic Gasket, Carbon Steel Gasket, Stainless Steel Gasket, Non-Metallic Gasket, Sanitary Gasket, CNAF Gasket etc. |

What is Low Pressure Gasket?

Low-pressure gaskets available in a variety of materials, forms, and sizes to suit diverse applications and environmental situations. Rubber, cork, paper, and different synthetic compounds are common materials used in low-pressure gaskets. These materials are selected based on temperature, pressure, and chemical compatibility with the fluid or gas being sealed.

The design of low-pressure gaskets is critical to their efficacy. They are typically designed with ridges, grooves, or moulded shapes to help establish a tight seal when pushed between mating surfaces. Proper installation and torque application are also required to guarantee that the gasket remains intact and prevents leakage over time. While low-pressure gaskets cannot resist high-pressure settings, they are essential for sealing applications that require moderate pressure.

Piping Projects India is a leading Low Pressure Gasket Manufacturer in India. As a result, it provides a diverse range of alternatives, ensuring that customers have access to high-quality Low Pressure Gaskets that may be adjusted to their specific application requirements. Low Pressure Gaskets are available in a variety of diameters and choices, as described below.

Low Pressure Gasket Chemical Composition

A prominent Low Pressure Gasket Manufacturer in India, specializes in ensuring exceptional quality through precise chemical composition. Our Low Pressure Gasket is dependable, robust, and performs optimally, meeting and exceeding industry standards in India and elsewhere.

| Material | Chemical Composition |

|---|---|

| Rubber | Mainly composed of polymers such as styrene-butadiene rubber (SBR), nitrile rubber (NBR), neoprene (CR), EPDM (ethylene propylene diene monomer), or silicone rubber. These polymers may include additional chemical additives such as vulcanizing agents, plasticizers, and antioxidants. Specific chemical values can vary widely depending on the type of rubber and its intended application. |

| Cork | Primarily composed of suberin, a complex mixture of fatty acids and waxy substances found in the cell walls of cork oak trees. Cork also contains lignin, cellulose, and other organic compounds. The exact chemical composition of cork can vary depending on factors such as the source of the cork and the processing methods used. |

| Paper | Made predominantly of cellulose fibers derived from wood pulp, along with various fillers, binders, and additives. Cellulose is a complex carbohydrate composed of glucose molecules linked together in long chains. The chemical composition of paper can vary depending on the type of pulp used, the processing methods, and any additives incorporated during manufacturing. |

| Synthetic Compounds | These include materials such as fluorocarbon elastomers (e.g., Viton), polytetrafluoroethylene (PTFE, Teflon), and various other synthetic polymers. These materials are typically composed of carbon, hydrogen, fluorine, and other elements, depending on the specific polymer composition. The chemical values for synthetic compounds can vary widely depending on the polymer structure and any additives used to enhance performance characteristics. |

WHERE CAN Low Pressure Gasket BE USED?

Low-pressure gaskets are used in a variety of sectors and systems where sealing is required at relatively low pressures. These gaskets are widely used in plumbing systems to seal pipes, fittings, and fixtures. They prevent water and other fluids from leaking into domestic plumbing, irrigation systems, and industrial pipe networks. Low-pressure gaskets are also used in vehicle engines to seal components including valve covers, oil pans, and intake manifolds.

Low Pressure Gasket Mechanical Properties

As a top Low Pressure Gasket Supplier in India, Our Low Pressure Gasket offers superior mechanical properties, ensuring long-term endurance in critical applications. In India's industrial climate, our precision-engineered equipment performs well and lasts long.

| Mechanical Property | Description | Typical Values/Range |

|---|---|---|

| Compressibility | Ability to deform and fill irregularities under pressure to create a seal. | 15% to 40% of original thickness |

| Elasticity | Ability to return to its original shape after compression or deformation. | Moderate to high elasticity |

| Tensile Strength | Maximum amount of tensile stress the material can withstand before breaking. | 500 psi to 3000 psi (depending on material) |

| Flexibility | Ability to bend or flex without cracking or breaking. | High flexibility |

| Resistance to Fluids | Ability to resist degradation when in contact with various fluids. | Resistant to water, oil, fuels, and chemicals |

WHERE SHOULD Low Pressure Gasket BE INSTALLED?

Low-pressure gaskets should be used in systems and components that require joint sealing and leak prevention at relatively low pressure circumstances. One prominent use is in plumbing systems, where gaskets are utilised to seal connections between pipes, fittings, and fixtures. They help to prevent leaks in water supply lines, drainage systems, and irrigation networks, ensuring that plumbing infrastructure in residential, commercial, and industrial environments runs efficiently and safely.

Low Pressure Gasket WIDELY USE IN?

Low Pressure Gasket Size Chart

| Gasket Type | Size Range | Typical Applications |

|---|---|---|

| Round O-ring | 1 mm to 50 mm diameter | Sealing of fluid and gas connections in machinery, pumps, and hydraulic systems. |

| Flat Gasket | Thickness: 0.5 mm to 10 mm | Sealing of flange connections in pipelines, plumbing systems, and automotive engines. |

| Square Gasket | Various dimensions, commonly ranging from 5 mm x 5 mm to 100 mm x 100 mm | Sealing of square or rectangular-shaped joints in machinery, equipment, and enclosures. |

| Custom Gaskets | Custom sizes and shapes based on specific requirements and designs | Tailored to fit unique sealing needs in specialized machinery, electronics, and industrial applications. |

Things To Consider When Buying Low Pressure Gasket

Supplying Low Pressure Gasket to Following Cities:

Piping Projects India is a leading Low Pressure Gasket Manufacturer in India. We proudly supply high-quality Low Pressure Gasket to major cities in India. We are known in the market as the India’s leading Low Pressure Gasket Supplier for a long time.

| Cities We Supply | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Raigad | Pune | Nashik | Nagpur | Mumbai | |||||

| Ahmednagar | Rajkot | Kolkata | Vadodara | Jalandhar | |||||

Get in Touch