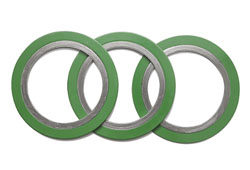

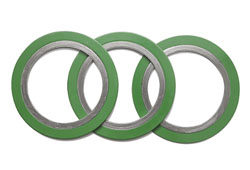

Piping Projects India is one of the leading Inconel Gasket Manufacturer in India. These Inconel Gaskets can also be machined and produced to match our customers' specific piping requirements. Inconel Gasket is the same as plates; nevertheless, the heaviness of the same is more than the ordinary plane plate based on forecasts (Chequers). Our organization is one of the largest Inconel Gasket Supplier in India. Our given variety of Inconel Gasket is widely acknowledged for its dimensional precision and durable construction, and it is available at very inexpensive costs to our valued customers.

Inconel Gasket

Trusted

Supplier

Genuine

Product

Easy

purchase

What is Inconel Gasket?

Inconel Gaskets are sealing components constructed of Inconel, a nickel-chromium-based superalloy recognized for its remarkable resistance to high temperatures, corrosion, and oxidation. Inconel Gaskets are frequently utilized in industries such as aerospace, chemical processing, oil and gas, and marine engineering, where severe temperatures and reliable sealing are required.

Inconel Gaskets are more corrosion resistant than many other materials, including stainless steel and carbon steel. They are extremely resistant to corrosion from acids, alkalis, seawater, and other corrosive substances, making them ideal for sealing applications in harsh environments. Furthermore, Inconel Gaskets offer exceptional mechanical qualities, such as high tensile strength, fatigue resistance, and toughness, ensuring long-term dependability and endurance in challenging industrial environments.

Piping Projects India is a leading Inconel Gasket Manufacturer in India. As such, it offers a diverse selection of options, guaranteeing that customers have access to high-quality Inconel Gaskets that can be customized to meet their individual application needs. Inconel Gaskets are available in a range of diameters and options, some of which are shown below.

Inconel Gasket Chemical Composition

A prominent Inconel Gasket Manufacturer in India, specializes in ensuring exceptional quality through precise chemical composition. Our Inconel Gasket is dependable, robust, and performs optimally, meeting and exceeding industry standards in India and elsewhere.

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 50 - 70 |

| Chromium (Cr) | 14 - 23 |

| Iron (Fe) | 5 - 20 |

| Molybdenum (Mo) | 2 - 3 |

| Copper (Cu) | 0.5 - 2 |

| Titanium (Ti) | 0.2 - 0.6 |

| Aluminum (Al) | 0.2 - 0.6 |

| Cobalt (Co) | 1.0 max |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 0.5 max |

| Carbon (C) | 0.08 max |

| Sulfur (S) | 0.015 max |

| Phosphorus (P) | 0.015 max |

WHERE CAN Inconel Gasket BE USED?

Inconel Gaskets are used in a variety of sectors and environments where harsh circumstances require high performance and resilience. They are primarily utilized in aerospace engineering to seal crucial components in aircraft engines, turbines, and exhaust systems, which are exposed to high temperatures, pressures, and corrosive conditions. Furthermore, in the chemical processing industry, Inconel Gaskets are critical for sealing reactors, piping systems, and containers that contain corrosive chemicals and aggressive fluids, maintaining operational safety and integrity.

Inconel Gasket Mechanical Properties

As a top Inconel Gasket Supplier in India, Our Inconel Gasket offers superior mechanical properties, ensuring long-term endurance in critical applications. In India's industrial climate, our precision-engineered equipment performs well and lasts long.

| Mechanical Property | Value |

|---|---|

| Tensile Strength | 550 - 850 MPa |

| Yield Strength | 240 - 650 MPa |

| Elongation | 30 - 60% |

| Hardness (Brinell) | 150 - 400 HB |

| Modulus of Elasticity | 190 - 220 GPa |

| Poisson's Ratio | 0.3 - 0.35 |

| Thermal Conductivity | 7 - 12 W/m·K |

| Specific Heat Capacity | 420 - 460 J/kg·K |

| Melting Point | 1300 - 1350°C |

WHERE SHOULD Inconel Gasket BE INSTALLED?

Inconel Gaskets are ideally suited for use in situations with intense temperatures, pressures, and corrosive chemicals. Inconel Gaskets are primarily used in the aerospace industry, where they are used in aircraft engines, turbines, and exhaust systems. These crucial components operate at extremely high temperatures and pressures, and Inconel Gaskets ensure that the aircraft's propulsion systems remain intact and perform properly.

Inconel Gasket WIDELY USE IN?

Inconel Gasket Dimension Table

| Gasket Type | Nominal Size (inches) | Outer Diameter (OD) (inches) | Inner Diameter (ID) (inches) | Thickness (inches) |

|---|---|---|---|---|

| Spiral Wound Gasket | 1/2 - 24 | Varies | Varies | 1/8 - 3/8 |

| Ring Type Joint (RTJ) | 1/2 - 24 | Varies | Varies | Standardized |

| Flat Gasket | Custom | Custom | Custom | Custom |

Things To Consider When Buying Inconel Gasket

Application & uses of Inconel Gasket

Supplying Inconel Gasket to Following Cities:

Piping Projects India is a leading Inconel Gasket Manufacturer in India. We proudly supply high-quality Inconel Gasket to major cities in India. We are known in the market as the India’s leading Inconel Gasket Supplier for a long time.

| Cities We Supply | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Raigad | Pune | Nashik | Nagpur | Mumbai | |||||

| Ahmednagar | Rajkot | Kolkata | Vadodara | Jalandhar | |||||

Get in Touch